About Us

Introduction to CTN-A

Certified Thermographers Network – Africa (CTN-A) is an African body established to unify, support, and regulate professionals and organizations involved in infrared thermography services across the continent. As the demand for non-invasive diagnostic technologies grows in industries such as energy, manufacturing, construction, mining, and utilities, CTN-A serves as the central authority for ensuring excellence in thermography practices.

Mission

Our mission is to maintain a robust and credible registry of certified thermographers, standardize qualification and certification frameworks, promote the use of calibrated infrared thermography equipment, and facilitate the sharing of knowledge, experience, and best practices. CTN-A provides a platform for continuous professional development, fosters collaboration across borders, and ensures that Thermographers from Africa remain globally competitive.

Vision

By bringing together skilled professionals, training institutions, equipment suppliers, and clients, CTN-A is building a trusted ecosystem where quality, safety, and technical integrity are at thecore of every infrared thermography project carried out on the continent.

Code of Ethics

This Code of Ethics is the foundation of professional practice for all CTN-A members. By adhering to these principles, thermographers demonstrate a shared commitment to trust, integrity, and excellence in the field of infrared thermography across Africa.

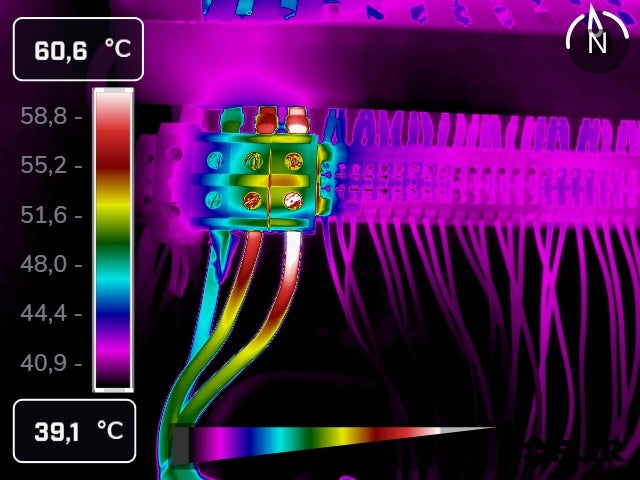

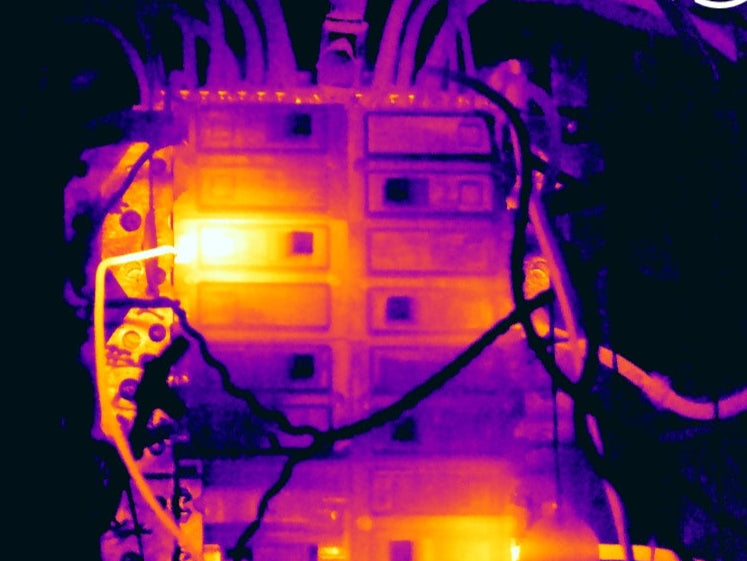

Electrical

A certified thermographer is responsible for conducting safe and accurate infrared inspections of electrical systems to identify hotspots, faulty connections, overloaded circuits, and equipment anomalies. Duties include preparing equipment, capturing thermal images under load, interpreting temperature patterns, documenting findings in detailed reports, and recommending corrective actions to prevent failures and ensure system reliability.

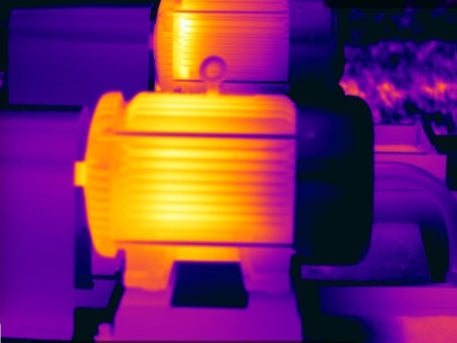

Mechanical

In mechanical thermal surveys, a certified thermographer is responsible for detecting heat-related issues in rotating and static equipment such as motors, bearings, pumps, and conveyors. Duties include capturing thermal images during operation, analyzing heat patterns to identify misalignment, friction, imbalance, or lubrication problems, and compiling reports with actionable insights to support maintenance planning and equipment reliability.

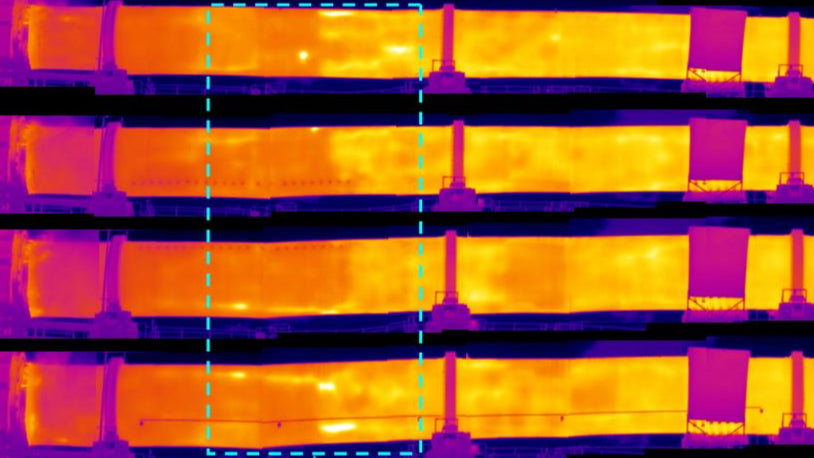

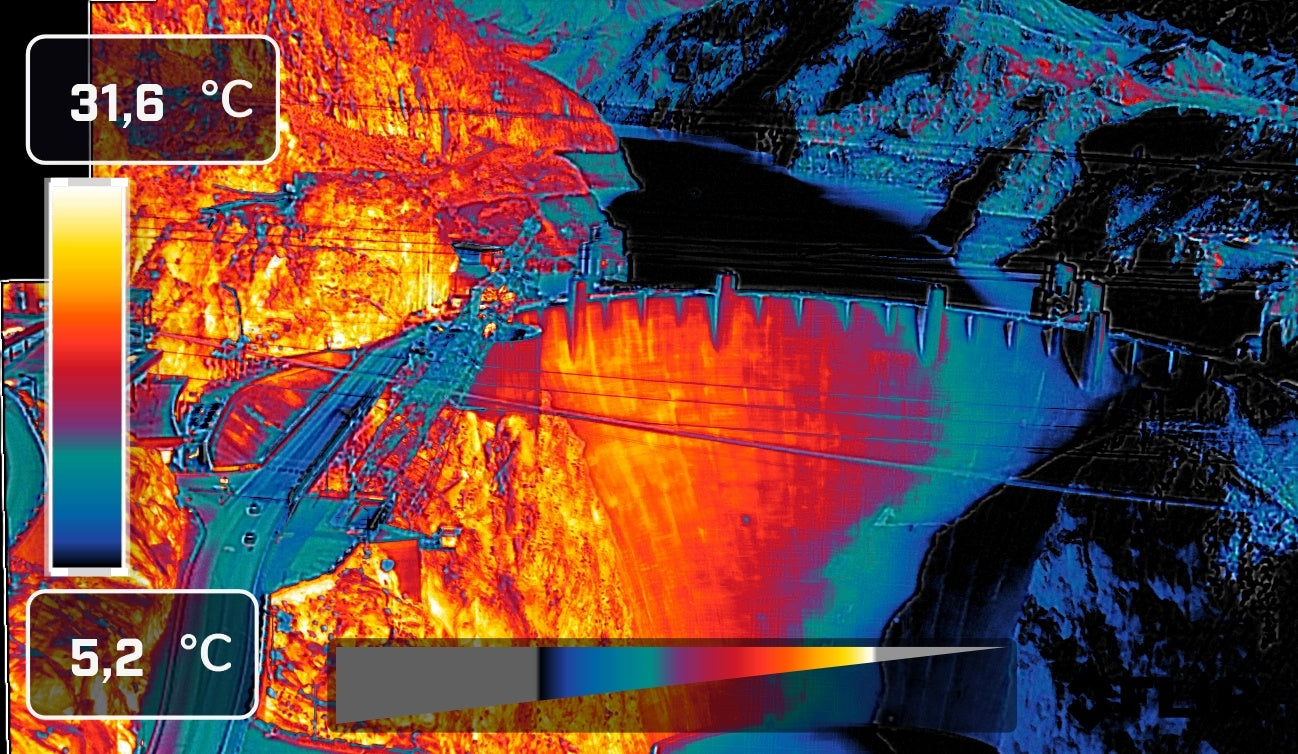

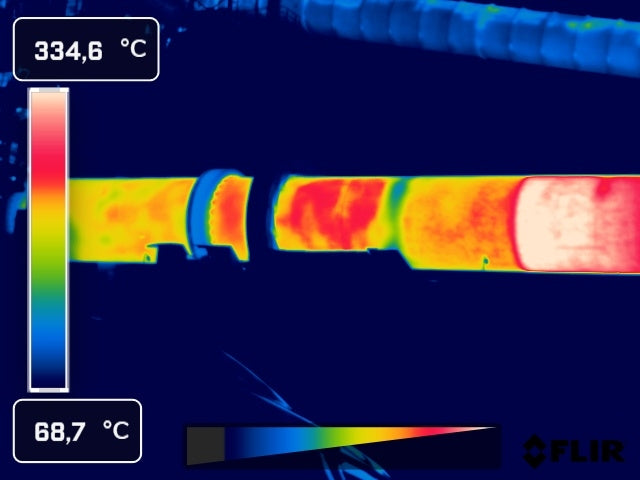

Refractory

During refractory thermal surveys, a certified thermographer assesses the thermal integrity of high-temperature linings in furnaces, kilns, and boilers. Responsibilities include capturing thermal images to detect insulation breakdown, hot spots, and heat loss, analyzing thermal gradients to identify structural concerns, and providing detailed reports to support preventive maintenance, safety, and energy efficiency.

Optical Gas Imaging (OGI)

In optical gas imaging surveys, a certified thermographer uses specialized infrared cameras to detect and visualize fugitive gas emissions from pipelines, valves, flanges, and processing equipment. Responsibilities include safely conducting inspections, identifying gas leaks not visible to the naked eye, documenting emission sources, and providing reports to support environmental compliance, safety, and maintenance planning.

Medical

In medical thermal imaging, a certified thermographer captures and analyzes thermal patterns of the human body to support early detection of inflammation, circulatory issues, or abnormal physiological activity. Duties include ensuring proper imaging protocols, maintaining patient comfort and privacy, producing high-resolution thermal scans, and collaborating with healthcare professionals to provide accurate, non-invasive diagnostic support.